Construction sites are dynamic environments where tasks, equipment, and conditions can change from hour to hour. These shifting elements create a wide range of potential hazards, from falls and struck-by incidents to equipment malfunctions and environmental risks. Because of this constant movement, safety cannot depend on guesswork. It must be planned, clear, and consistent. That is exactly why a construction job hazard analysis is such a critical part of modern safety practices.

A construction job hazard analysis, often shortened to JHA, is a structured approach to identifying risks before work begins. It breaks a task into steps, examines each one for potential hazards, and outlines the safest way to complete the work. While this concept may sound simple, its impact is profound. A well-prepared JHA protects workers, strengthens communication, and reduces the chance of preventable injuries. More importantly, it reinforces a culture of awareness and responsibility where everyone understands their role in keeping the jobsite safe.

Why a Construction Job Hazard Analysis Is Essential

A construction site can change quickly. Weather conditions worsen, equipment malfunctions, surfaces shift, or new workers arrive with different levels of experience. With so many variables, hazards can easily go unnoticed. A construction job hazard analysis ensures that risks are recognized before the first tool is lifted.

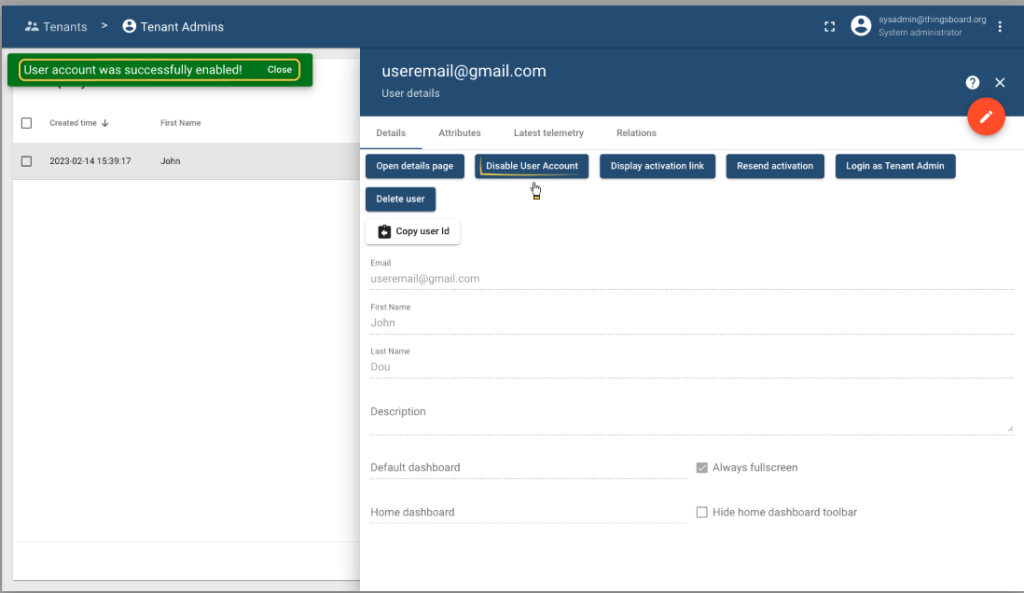

The purpose of a JHA is not to create additional paperwork. It is to encourage foresight. When workers understand the hazards associated with their tasks, they make better decisions. They take fewer shortcuts, watch out for one another, and feel empowered to speak up when something is unsafe.

A JHA also supports planning. By identifying risks ahead of time, supervisors can determine what controls or equipment are needed to complete the task safely. This preparation prevents delays, confusion, and last-minute scrambling on the jobsite.

Breaking Tasks Into Clear, Manageable Steps

One of the main strengths of a construction job hazard analysis is its simplicity. Instead of viewing a job as one large task, the JHA divides it into small steps. Each step is examined individually to identify hazards and determine safe practices.

For example, a task like installing a beam may involve:

• Preparing the work area

• Inspecting equipment

• Lifting the beam

• Securing it in place

• Verifying alignment

Each step contains unique hazards. By analyzing them separately, workers gain a clearer understanding of where risks exist and how to control them. This level of detail helps prevent minor oversights that could lead to major accidents.

Improving Communication and Team Awareness

A construction job hazard analysis is not meant to be completed alone. It is most effective when teams discuss the steps together. These conversations help workers understand the task as a group, clarify roles, and share insights that others may not have considered.

This collaborative approach promotes a culture of communication. When workers feel comfortable discussing hazards, they are more likely to report problems early and ask questions when they are unsure. Clear communication reduces assumptions and ensures that everyone is on the same page.

In environments where crews may change frequently or include workers with varying experience levels, these discussions become even more valuable. A JHA ensures that no one begins a task without knowing the expectations and potential risks.

Reducing Injuries and Preventable Accidents

Many construction injuries happen because hazards were not recognized in time. A JHA forces workers and supervisors to think ahead and address potential issues before work begins. This proactive approach significantly reduces the likelihood of injuries.

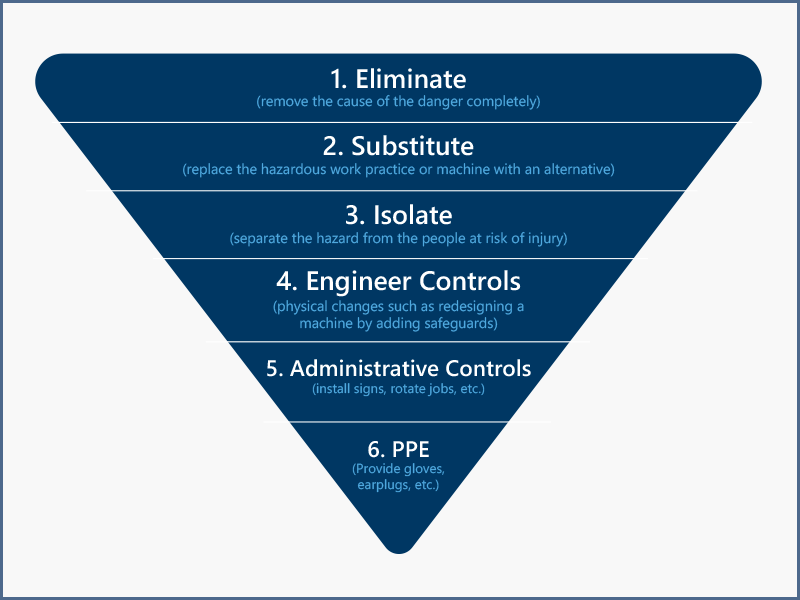

Common hazards identified through a construction job hazard analysis include:

• Fall risks from ladders, scaffolds, or elevated surfaces

• Electrical hazards from exposed wiring or tools

• Equipment pinch points

• Struck-by hazards from moving vehicles or falling materials

• Chemical exposure

• Weather-related dangers

Once hazards are identified, the JHA outlines the control measures needed to reduce or eliminate them. These may include guardrails, PPE, lockout procedures, spotters, signage, or environmental monitoring. By recognizing hazards early, the team takes steps that prevent accidents instead of reacting after something goes wrong.

Strengthening Safety Culture

A construction job hazard analysis is more than a safety form. It is a reflection of the values of the jobsite. When workers see that management takes time to discuss hazards, provide training, and ensure safe practices, it sends a powerful message: safety matters.

Over time, consistent use of JHAs builds a culture where workers feel supported. They recognize that reporting hazards is not an inconvenience. It is part of a shared commitment to protecting one another. This environment encourages workers to take ownership of safety and make responsible decisions throughout the day.

Supporting New Workers and Specialized Tasks

Construction crews often include individuals with different levels of experience. New workers may not fully understand jobsite hazards, and even experienced workers may be unfamiliar with specialized tasks. A JHA provides clarity and confidence for everyone involved.

By reviewing each step of the job, supervisors help new workers learn expectations and understand risks without feeling overwhelmed. More complex tasks also benefit from a detailed breakdown, ensuring that no assumptions are made about worker knowledge or experience.

Adapting to Changing Conditions

Because construction environments shift, a JHA must be flexible. Weather changes, new equipment arrives, or the work area may evolve as a project progresses. Effective teams review and update their construction job hazard analysis to reflect these changes.

This adaptability keeps the JHA relevant. It remains a living document that supports daily decision-making rather than something completed once and forgotten.

Conclusion

A construction job hazard analysis is one of the most powerful tools in the safety process. It encourages workers to think ahead, communicate clearly, and take control of the hazards around them. By breaking tasks into steps, identifying risks, and planning safe work practices, a JHA reduces injuries and strengthens teamwork.

In an industry where conditions shift rapidly and hazards can appear unexpectedly, this proactive approach is essential. A well-prepared JHA not only protects workers but also enhances efficiency, builds trust, and fosters a culture where safety is shared by everyone on the jobsite.

If you’d like, I can also create toolbox talks, shorter summaries, printable versions, or additional articles for related construction safety topics.